Measuring Pressure Simplified

Understanding Pressure and Its Importance

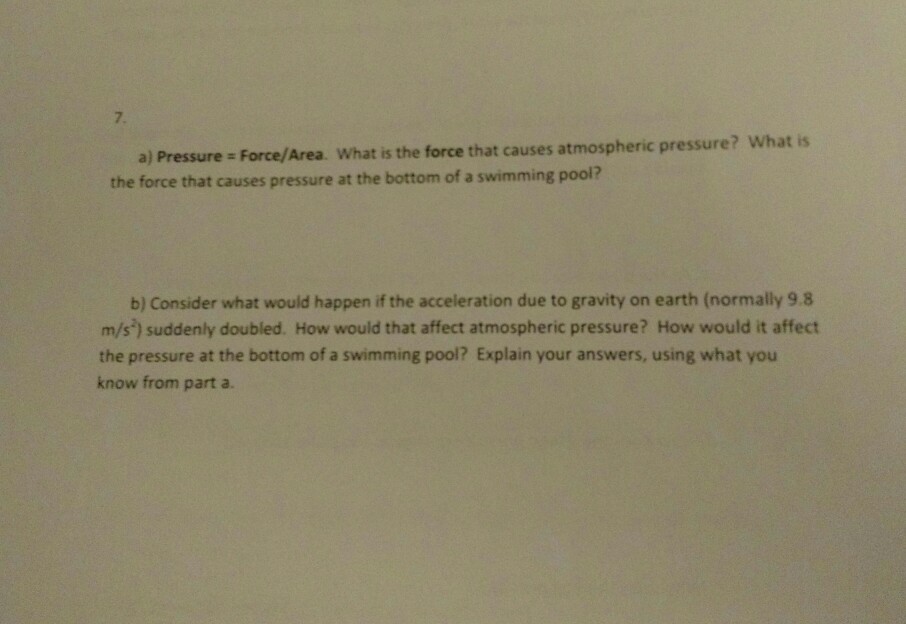

Pressure is a fundamental concept in physics that plays a crucial role in various aspects of our lives. It is a measure of the force exerted per unit area on an object or surface. Pressure is essential in understanding natural phenomena, designing infrastructure, and ensuring safety in various industries. Despite its importance, measuring pressure can be a daunting task, especially for those without a background in physics or engineering.

The Basics of Pressure Measurement

To measure pressure, we need to understand the different types of pressure and the units used to express them. There are two primary types of pressure: absolute pressure and gauge pressure. Absolute pressure is the total pressure at a given point, including atmospheric pressure, while gauge pressure is the pressure measured relative to atmospheric pressure.

The most common units of pressure measurement are:

- Pascals (Pa)

- Pounds per square inch (psi)

- Kilopascals (kPa)

- Bars

- Atmospheres (atm)

Methods of Measuring Pressure

There are several methods of measuring pressure, each with its own advantages and limitations. Some of the most common methods include:

- Manometers: These are U-shaped tubes filled with a fluid, typically water or mercury, that measure pressure by observing the difference in height between the two columns.

- Bourdon tubes: These are curved tubes that straighten when pressure is applied, causing a needle to move on a calibrated scale.

- Piezoelectric sensors: These sensors use crystals that generate an electric charge when subjected to pressure, which is then measured by an electrical circuit.

- Digital pressure gauges: These are electronic devices that use sensors and microprocessors to measure pressure and display the results on a digital screen.

Choosing the Right Pressure Measuring Device

Selecting the right pressure measuring device depends on several factors, including:

- Accuracy: The required level of precision in the measurement.

- Range: The maximum and minimum pressures that need to be measured.

- Environmental conditions: The device’s ability to withstand temperature, humidity, and other environmental factors.

- Cost: The budget for the device and any additional costs, such as calibration and maintenance.

| Device | Accuracy | Range | Environmental Conditions | Cost |

|---|---|---|---|---|

| Manometer | ±1% | Up to 100 psi | Temperature: -20°C to 100°C, Humidity: 0-100% | $50-$500 |

| Bourdon tube | ±2% | Up to 1000 psi | Temperature: -20°C to 200°C, Humidity: 0-100% | $100-$1000 |

| Piezoelectric sensor | ±0.5% | Up to 10000 psi | Temperature: -50°C to 200°C, Humidity: 0-100% | $500-$5000 |

| Digital pressure gauge | ±0.1% | Up to 10000 psi | Temperature: -20°C to 100°C, Humidity: 0-100% | $100-$1000 |

🔍 Note: The prices listed are approximate and can vary depending on the manufacturer and specific model.

Best Practices for Measuring Pressure

To ensure accurate and reliable pressure measurements, follow these best practices:

- Calibrate the device: Regularly calibrate the device to ensure accuracy and account for any drift over time.

- Choose the right unit: Select the correct unit of measurement for the specific application.

- Consider environmental factors: Account for temperature, humidity, and other environmental factors that may affect the measurement.

- Use proper installation and maintenance: Ensure the device is installed and maintained correctly to prevent damage and ensure accuracy.

In conclusion, measuring pressure is a crucial aspect of various industries and applications. By understanding the basics of pressure measurement, selecting the right device, and following best practices, you can ensure accurate and reliable pressure measurements.

What is the difference between absolute and gauge pressure?

+Absolute pressure is the total pressure at a given point, including atmospheric pressure, while gauge pressure is the pressure measured relative to atmospheric pressure.

What is the most common unit of pressure measurement?

+The most common units of pressure measurement are Pascals (Pa), pounds per square inch (psi), kilopascals (kPa), bars, and atmospheres (atm).

How often should I calibrate my pressure measuring device?

+Regular calibration is recommended to ensure accuracy and account for any drift over time. The frequency of calibration depends on the specific device and application.

Related Terms:

- What causes atmospheric pressure