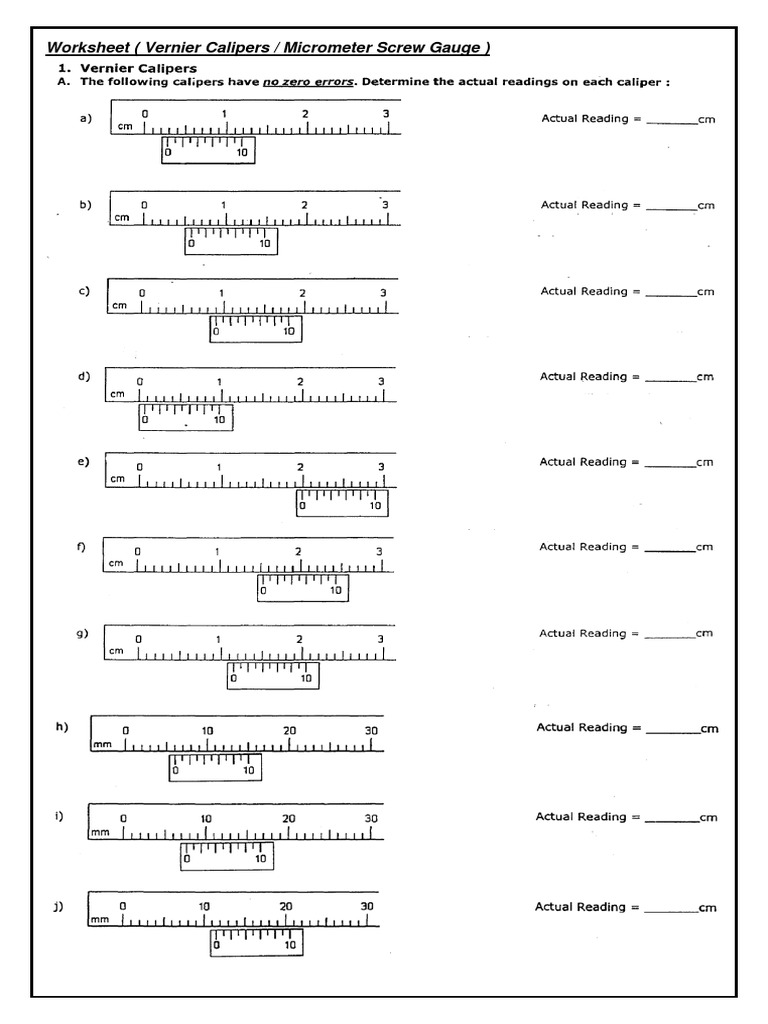

5 Essential Steps to Mastering the Dial Caliper

Understanding the Dial Caliper: A Precision Measuring Instrument

The dial caliper is a precision measuring instrument used to accurately measure the distance between two points, the thickness of an object, or the diameter of a circle. It is a versatile tool that is widely used in various industries, including engineering, manufacturing, and quality control. Mastering the use of a dial caliper is essential for anyone who needs to make precise measurements. In this article, we will outline the 5 essential steps to mastering the dial caliper.

Step 1: Choosing the Right Dial Caliper

With various types of dial calipers available in the market, choosing the right one can be overwhelming. When selecting a dial caliper, consider the following factors:

- Accuracy: Look for a dial caliper with high accuracy, typically ±0.001 inches or ±0.02 mm.

- Resolution: Choose a dial caliper with a high resolution, such as 0.0001 inches or 0.01 mm.

- Range: Select a dial caliper with a range that suits your measurement needs.

- Type: Decide between a digital or analog dial caliper, depending on your preference and application.

📝 Note: Consider the environment and application where the dial caliper will be used, as some models may be more suitable for specific industries or tasks.

Step 2: Understanding the Dial Caliper Components

Before using the dial caliper, it’s essential to understand its components and their functions:

- Jaw: The movable jaw is used to measure the distance between two points.

- Screw: The screw is used to adjust the jaw’s position.

- Dial: The dial displays the measurement reading.

- Lock: The lock is used to secure the jaw in place.

| Component | Function |

|---|---|

| Jaw | Measures distance between two points |

| Screw | Adjusts jaw's position |

| Dial | Displays measurement reading |

| Lock | Secures jaw in place |

Step 3: Taking Accurate Measurements

To take accurate measurements with a dial caliper, follow these steps:

- Clean the surface: Ensure the surface is clean and free of debris.

- Position the jaw: Place the jaw on the surface, ensuring it’s perpendicular to the surface.

- Adjust the screw: Adjust the screw to move the jaw to the desired position.

- Read the measurement: Read the measurement on the dial, taking note of the units.

📊 Note: Always take multiple measurements to ensure accuracy and account for any human error.

Step 4: Calibrating the Dial Caliper

Calibrating the dial caliper is essential to ensure accuracy. Follow these steps:

- Check the calibration certificate: Verify the calibration certificate to ensure the dial caliper is accurate.

- Perform a self-calibration: Follow the manufacturer’s instructions to perform a self-calibration.

- Check for wear and tear: Regularly inspect the dial caliper for wear and tear, and adjust or replace as necessary.

Step 5: Maintaining the Dial Caliper

To ensure the dial caliper remains accurate and functional, follow these maintenance tips:

- Store properly: Store the dial caliper in a dry, clean environment.

- Clean regularly: Regularly clean the dial caliper with a soft cloth and mild soap.

- Lubricate: Lubricate the screw and jaw regularly to prevent wear and tear.

The dial caliper is a precision measuring instrument that requires attention to detail and proper care. By following these 5 essential steps, you’ll be well on your way to mastering the dial caliper and taking accurate measurements.

In summary, mastering the dial caliper requires choosing the right instrument, understanding its components, taking accurate measurements, calibrating regularly, and maintaining the instrument properly. By following these steps, you’ll become proficient in using the dial caliper and take your measurement skills to the next level.

What is the difference between a digital and analog dial caliper?

+A digital dial caliper displays the measurement reading on an LCD screen, while an analog dial caliper displays the measurement reading on a mechanical dial.

How often should I calibrate my dial caliper?

+It’s recommended to calibrate your dial caliper at least once a year, or as specified by the manufacturer.

What is the accuracy of a typical dial caliper?

+A typical dial caliper has an accuracy of ±0.001 inches or ±0.02 mm.

Related Terms:

- Dial caliper practice

- Dial caliper reading

- Dial caliper test

- Micrometer worksheet

- Dial caliper Simulator